China Wholesale Wine Bottle Labeler Manufacturers - Express parcel scanning printing labeling packaging machine – UBL

China Wholesale Wine Bottle Labeler Manufacturers - Express parcel scanning printing labeling packaging machine – UBL Detail:

Product Introduction

Backing machine, commonly known as strapping machine, is the use of strapping tape winding products or packaging cartons, and then tighten and fuse the two ends of the packaging belt products through the thermal effect of the machine.

The function of the strapping machine is to make the plastic belt close to the surface of the bundled package, to ensure that the package is not scattered in transportation and storage because of the bundling is not firm, at the same time, it should also be neatly bundled and beautiful!

It is mainly used for packing cartons, paper packages, willow boxes, cloth packages and other products in commercial, postal, railway, banking, food, medicine, books and periodicals distribution industries.

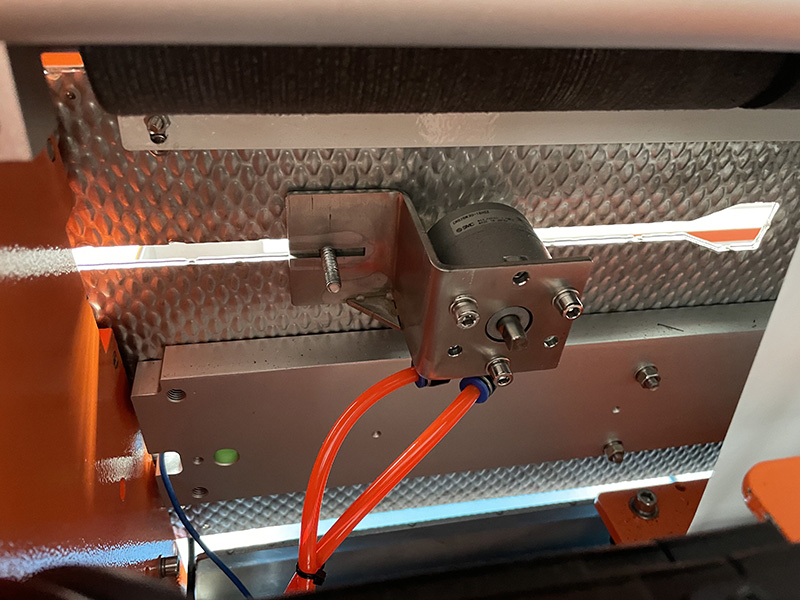

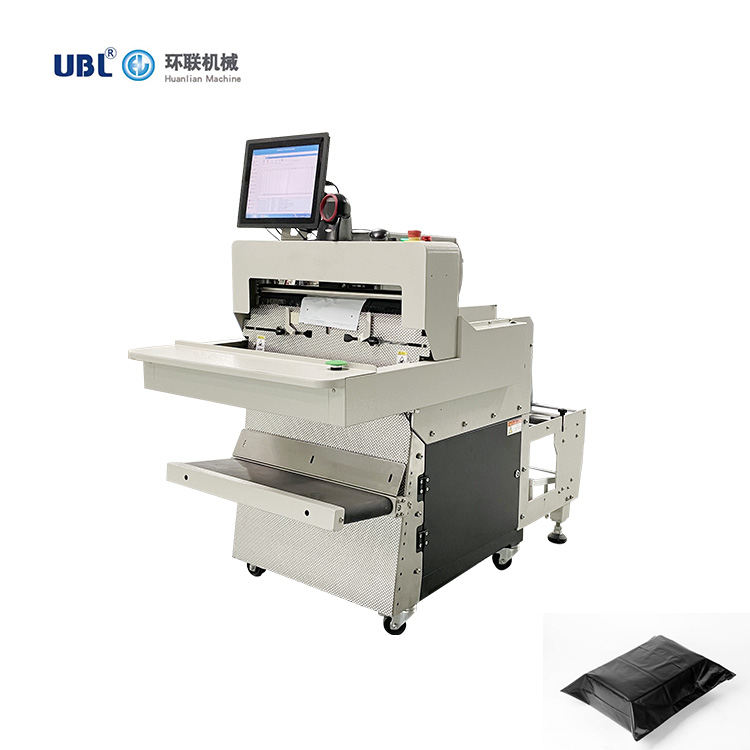

This product is a patented product of the intelligent express strapping machine independently developed by our company, which is specially designed for e-commerce logistics users. The whole machine is based on high-performance industrial control computer, and provides integrated solutions such automatic scanning, automatic weighing, sealing film, automatic printing, and automatic pasting express order. At the same time, we can offer the mainstream ERP system and WMS system according to the needs of customers. We provide the overall solution for the shipment of plastic film goods packaging for customers.

Working Principle

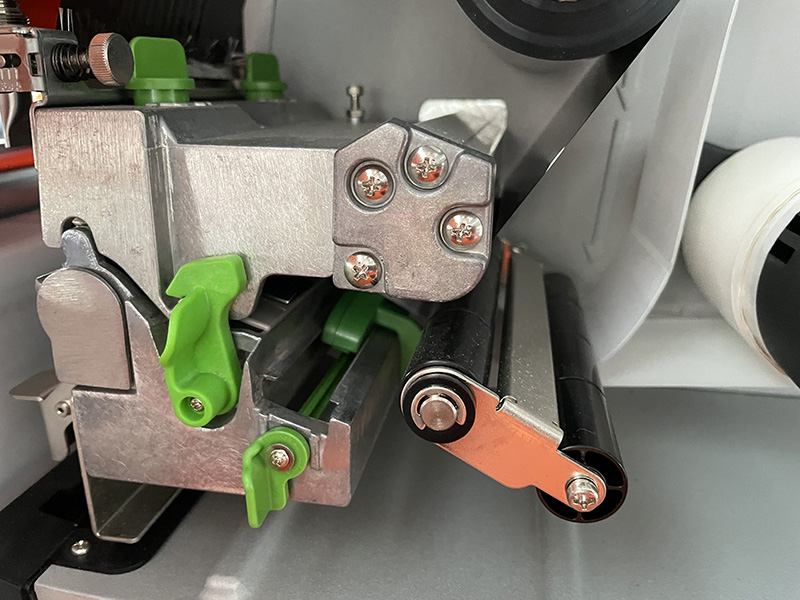

After inserting the packing tape, the machine can automatically complete the binding process of gathering tape, heat sealing, cutting and untying tape.And it has the function of automatic stop.

The working speed is fast, high efficiency, time – and labor-saving, and the tying quality is high.To ensure that the package is not scattered in transportation and storage due to the tying is not firm, but also should be tied neatly and beautiful.

Product Characteristics

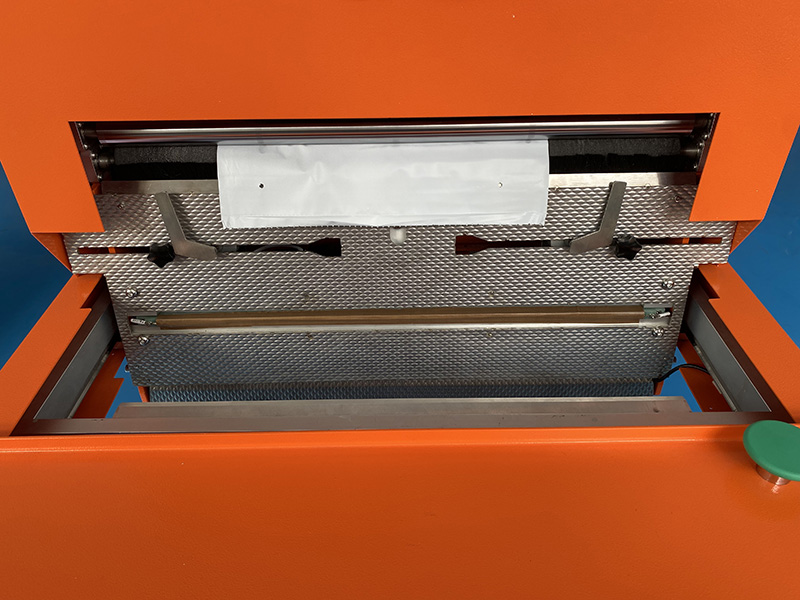

1. In order to prevent the occurrence of the express order sheet, the face sheet information is automatically generated by the system and automatically printed and pasted without manual intervention.

2. Only one person can operate, 1100 bags can be packed per hour.

3. Use technology to effectively eliminate static hazards, work smoothly and reliably, improve work efficiency.

4. anti-pinch, anti-scalding, anti-misoperation, safe to use.

5. Smart express package can be achieved with only 1.5 square meters.

Product Parameters

|

Description |

Parameter |

|

Plastic bag specifications |

PE film roll: diameter MAX300mm, film thickness 0.05-0.1mm, film width MAX700mm |

|

Express order size |

Width MAX100mm, length MIN100mm.180mm,or custom made |

|

Packing speed |

1100 packs / hour |

|

Interface |

Mouse,Touch screen, virtual keyboard |

|

Display |

7/12-inch LCD |

|

Communication access |

Ethernet, USB, RS232 |

|

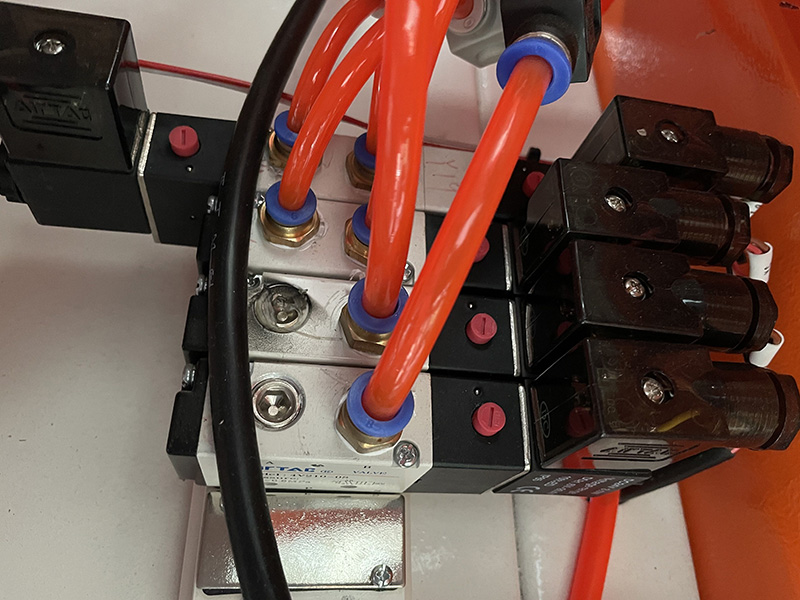

Air pressure |

0.7-0.9MPa |

|

Power supply |

AC220V, 50/60Hz Power: 1.5kW |

|

Equipment size |

Length: 1580mm Width: 850mm Height: 1420mm |

|

Weight |

200KG |

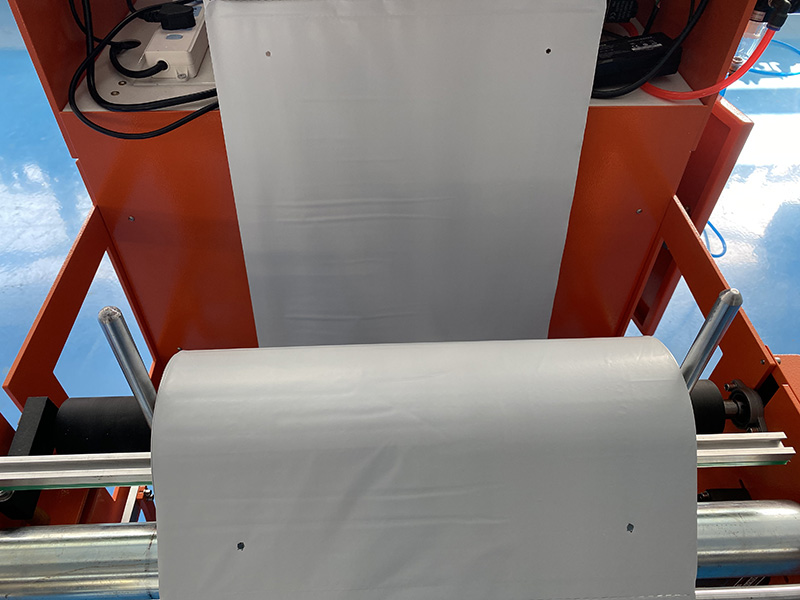

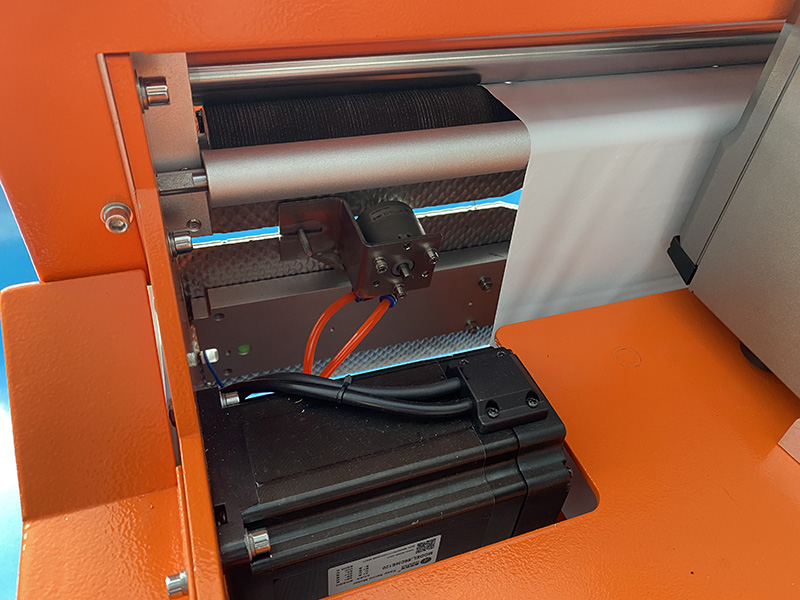

Machine Details

Common Problem

1. Do not send the belt, send the belt is not in place is mainly the quality of the packing belt is not straight, the packing belt is too soft, send the belt time is too short, the packing belt storage belt is insufficient, the gap adjustment is not in place.

2. Non-adhesive tape, non-adhesive tape is mainly caused by too much recycled material in the packing belt, improper adjustment of heating head temperature, incorrect position of the middle top knife, improper adjustment of strapping tightness.

3. The adhesive contact is mainly due to the improper selection of the packing belt with the groove and the packing belt, and the improper adjustment of the back belt limiter.

4. Packaging does not matter is the strapping tightness adjustment is improper, the clamping force knife wear.

Product detail pictures:

Related Product Guide:

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for China Wholesale Wine Bottle Labeler Manufacturers - Express parcel scanning printing labeling packaging machine – UBL , The product will supply to all over the world, such as: Cyprus, Italy, Melbourne, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!