Buckle bottom cartoning machine

Product Paramenters

|

BUCKLE BOTTOM CARTONING MACHINE

|

|

| Type |

HL-ZKC-02

|

|

Machine name

|

BUCKLE BOTTOM CARTONING MACHINE

|

|

power

|

220V 50Hz 2Kw

|

| Speed | 25~40 boxes /min |

|

box size range

|

L:120-280,W:50-120,H:30-100 mm

When the height and width of the box are the same, opening the box is risky

|

|

carton feeder height

|

500-600mm

|

|

carton thickness

|

350-400 g of white cardboard, the carton indentation is not less than 0.4mm,With pre-folding effect, ear pages and short pages need to be chamfered

|

|

Air pressure

|

200NL/min 0.6-0.8mpa

|

|

machine weight

|

about 1200KG

|

|

machine size

|

L*W*H:2800*700*1580mm

|

Function introduction

Basic functions

◆ This machine has a box rack, and a stack of boxes can be placed on the box rack

◆ Automatically take out boxes, open boxes, buckle bottoms, pack boxes, insert tongues and seal

◆ It can be used alone, or connected to the automatic feeding device in front, and can also be connected to labeling machines, weighing machines, packaging machines, and cartoning machines in the back to realize automated production lines

◆ Commonly used for boxing of various electronic products, cosmetics, food, hardware and other products

Optional functions:

◆ Optional instruction card issuing machine;

◆ Optional counting conveying device, etc.;

Equipment advantages:

◆ Use extended horizontal storage bin horizontal structure, the pressure will not change due to changes in the number of boxes, and the box opening performance is guaranteed. And it can continuously add boxes without stopping the machine;

◆ Standard double suction box opening mechanism (using upper + lower simultaneous double suction box opening mechanism, for square boxes/boxes that are not pre-folded enough/boxes that are too short, etc., can stably open the box to ensure the success rate of box opening);

◆ Every dynamic part of the body is covered with acrylic safety protection cover to ensure operation safety;

◆ The overall PLC and touch screen use Huichuan's bus control system, and the material pusher uses Huichuan's servo motor, which runs stably;

◆ After opening the box, there is an electric eye to detect whether the box opening is successful. If the box opening is unsuccessful, the material can be pushed to avoid damage to the product; at the same time, there is also a function of not opening the box if there is no material.

◆ All electric eyes use German sick to ensure the stability of the signal;

◆ The whole machine is made of stainless steel, which meets various production conditions;

◆ The conveying section can be disassembled and packaged to reduce the transportation volume and facilitate handling.

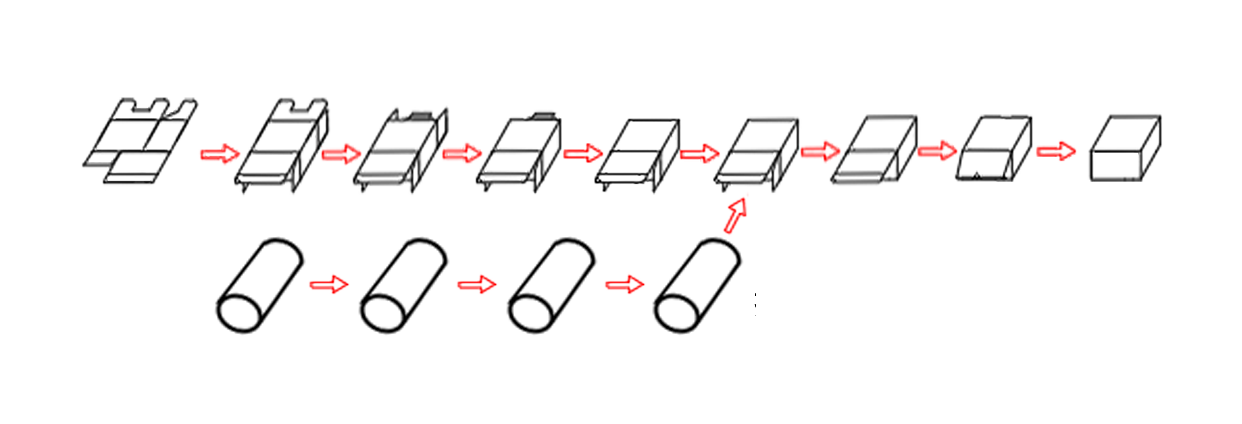

Boxing flowchart