Products

-

-

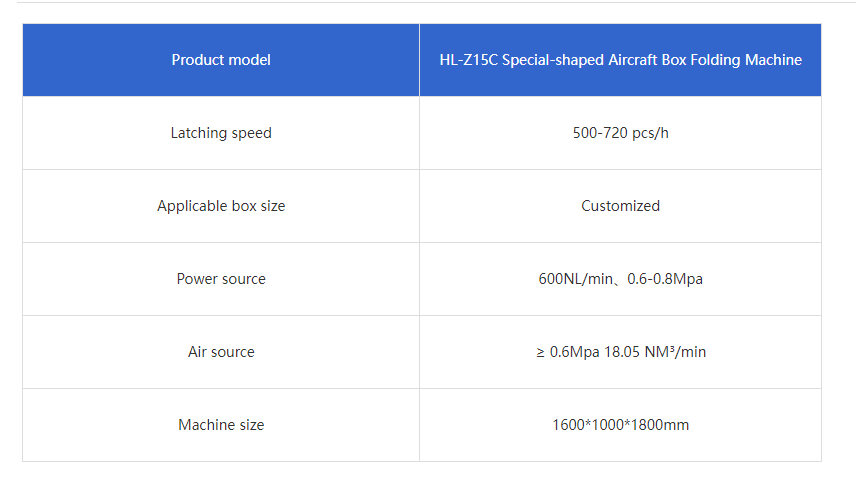

Abnormal shape Corrugated Mailer

Basic Functions

◆ The machine is equipped with an automatic box and feeding device. Once feeding is complete, the equipment automatically performs box folding actions.

◆ The equipment automatically retrieves boxes, compresses and forms them, folds the front and sides simultaneously, and completes both folding and page attachment in one operation. Finished products are output after folding is complete.

◆ Can be used as a standalone machine or connected to subsequent box packing production lines.

-

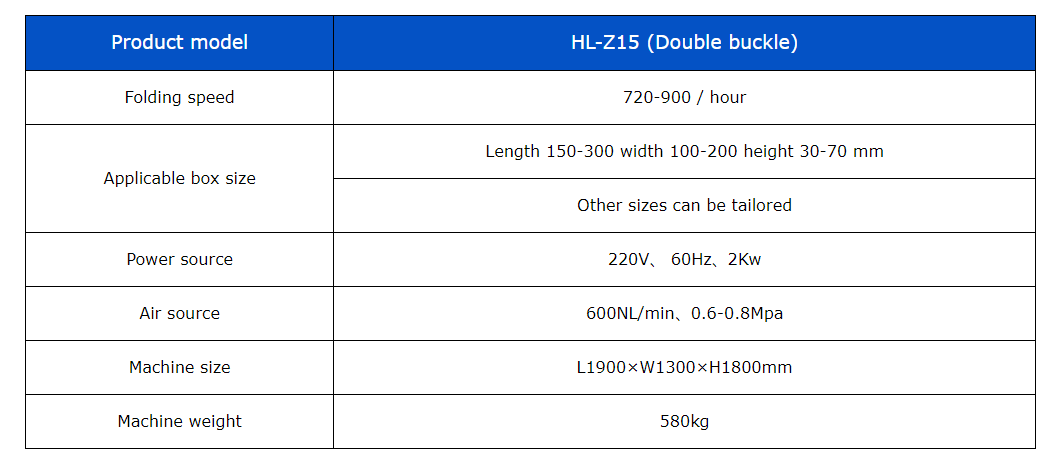

Corrugated Mailer(Standard version)

Basic function

◆ This machine includes box automatic adsorption feeding device, can put a stack of boxes on the box shelf, synchronous box fetching, pressing down forming, folding on both sides of the page synchronously completed; (You can also do three-sided gusset plate, the price is different), after the folding box is finished output;

◆ Can be used alone, can also be connected to the back of the box production line;

◆ Commonly used in various fruit boxes, electronic products, hardware products, toys, cosmetics, medical pharmaceutical industry and other aircraft box automatic folding box use.

Optional function

◆ Can be customized spray folding box machine.

◆ High speed folding machine can be customized.

-

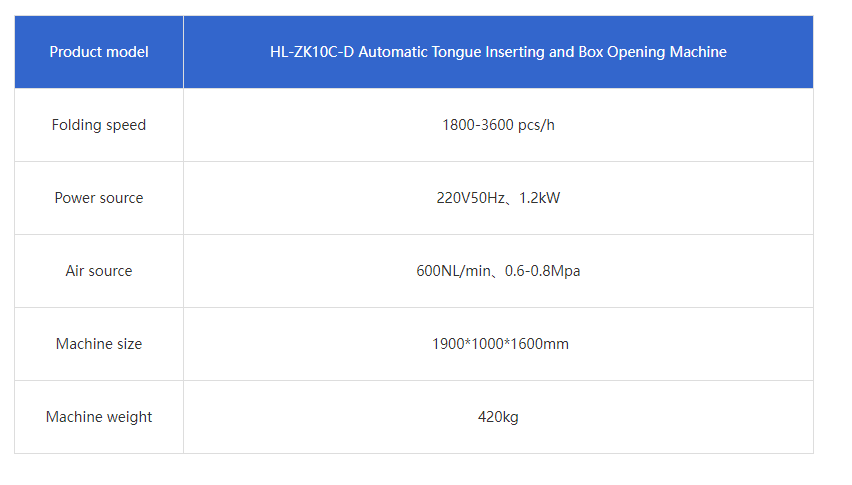

Fully automatic Tuck End Box

Basic Functions

◆ Simple and user-friendly machine design

◆ Economical, durable, safe, and low failure rate

◆ Manual placement of boxes into the magazine (compatible with boxes over 800mm)

◆ Automatic box retrieval and opening

◆Single-sided or double-sided tongue folding for box sealing

◆ Finished products can be conveyed to the assembly line or loading platform for manual product placement

-

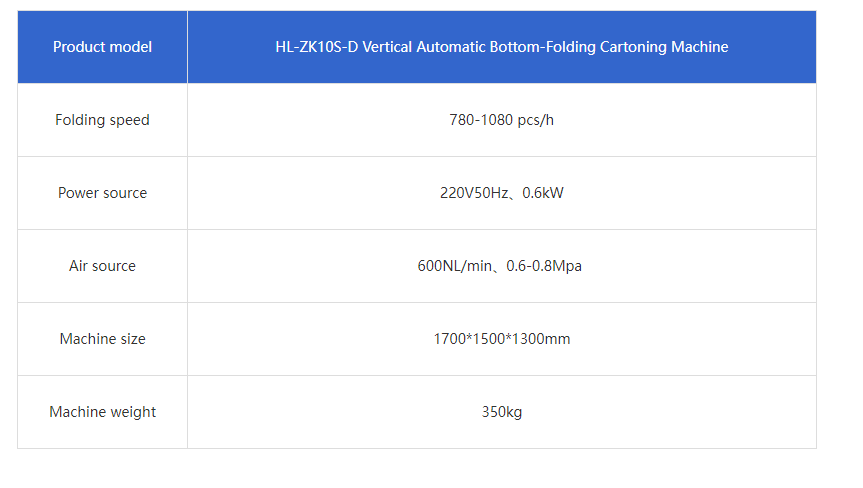

Snap lock bottom carton erecting machine

Basic function

◆ The design of the machine is simple, economic and durable, safe, low failure rate;

◆ It is suitable for packaging of the same carton size at the same time. If the carton size needs to be changed, it can be adjusted manually, which takes 10-15 minutes.

◆ This machine can be used in a single machine or with an automated packaging line.

◆ Widely used in electronic products, toys, food, e-commerce products, cosmetics, medical drugs and other industries;

◆ The design and production of the equipment meet the requirements of the production line process flow and plane layout, the appearance is beautiful and generous, and the manufacturing process is good.

◆ There is no carton alarm function.

◆ Box storage mechanism: more than 100 unformed cartons can be placed at a time (according to the thickness of the carton), and can be replenished at any time.

-

Corrugated Mailer Glue spraying sealing machine

Basic Functions

◆ This machine automatically feeds boxes, applies hot melt adhesive, and compresses the boxes into shape, finally completing the box sealing process. The sealing results are aesthetically pleasing, standard, stable, and secure.

◆ Widely used in automatic box sealing for various hardware tools, electronic products, toys, cosmetics, medical pharmaceuticals, and other industries.

-

.jpg)

Airplane box folding – Automatic boxing – Automatic lid closing – Real-time printing and labeling production line

Product Introduction

This packaging line realizes automatic folding and forming of airplane boxes, with robots automatically completing product loading, and an automatic box closing machine performing the closing action. It also features an automatic label applicator that prints and attaches product information labels to the top surface of the boxes in real-time.

Product Functions

◆ Airplane Box Folding Machine: Automatic feeding and folding of airplane boxes

◆ Robot Automatic Loading: Automatically picks and places materials into boxes on the conveyor line / manual loading station optional

◆ Automatic Box Closing Machine: Automatically completes the closing action for airplane boxes

◆ Real-time Printing and Labeling Machine: Prints product information labels and automatically applies them to the top surface of the airplane boxes

-

Automatic Cartoning – Weight Inspection – Three-dimensional Packaging Line

Product Introduction

This packaging line realizes automatic box packing for strip products, and completes weighing inspection (with automatic rejection), as well as automatic three-dimensional film packaging.

Product Functions

◆ Automatic Box Packing Machine: Automatically opens boxes, packs products into boxes automatically, and seals the boxes after packing is completed.

◆ Weighing Inspection Machine: Automatically inspects packed products. Products that do not meet the weight requirements will be automatically rejected.

◆ Three-dimensional Film Packaging Machine: Using roll film bag-making method, tear lines are automatically applied to the packaging film. After the machine automatically makes bags, it performs three-dimensional film packaging and sealing for the boxes.

-

High-speed Cartoning Machine

This machine can perform double suction and boxing, doubling the efficiency.

-

Servo Cartoning machine

With bus control system and servo absolute positioning control, the equipment operates stably, and model changeover, debugging and maintenance are simpler and faster.

-

Bag making clothing folding machine + express packaging machine

1. Fully automatic folding and bagging machine: realize the integrated process of automatic folding + automatic bagging for clothing and other products, reducing manual intervention.

2. Fully automatic bag making mechanism: can make packaging bags in real time according to product size, and support customized bag types (such as flat bags, self-sealing bags, etc.)

3. Express packaging mechanism: semi-automatic packaging machine supports various packaging methods such as express bags -

Blanket Automatic Folding Packaging Machine

1. This device completes product folding through automatic material pulling mechanism, left and right rolling mechanism, double longitudinal folding mechanism, and automatic pre pressing mechanism,; The bag making is completed by the roll film feeding mechanism, automatic film cutting mechanism, and automatic bag pulling mechanism: The product bagging is completed by an automatic bag opening mechanism, an automatic bag supporting mechanism, and a material clamping and transferring mechanism with a sealing mechanism at the tail.

2. The design of each component of the equipment is carried out according to the efficiency requirements of 400-600 PCS/H:

3. The device input interface is touch controlled and can store 40 types of clothing folding parameters for easy selection.