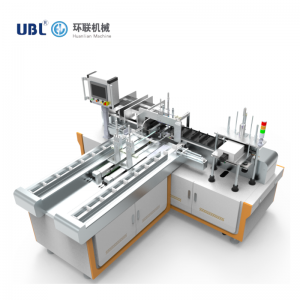

Fully automatic punching and bagging machine

Application Scenarios

Widely used for packaging products in the fields of life,learning,electronics,and healthcare.

Application scenario:Various types of 3C boxes,power data cables,remote controls,mobile phone cases,with hooks on the outside of the box,requiring drilling.

Product Paramenters

| Type | YH-ZA11B-12 |

|

Machine name

|

AIRPLANE SHAPE BOX FOLDING MACHINE (HIGH-SPEED MODEL) |

|

power

|

220V、3Kw

|

| Speed | 900-1200pcs/h |

| Applicable product size |

Sizes available to order

(Recommended for single specifications)

|

|

Air pressure

|

0.5-0.7mpa

|

|

machine weight

|

600KG

|

|

machine size

|

L*W*H:2240*1400*1560mm

|

Function introduction

EQUIPMENT FUNCTIONS AND CHARACTERISTICS:

1.The equipment mechanism is composed of automatic film feeding mchanism,automatic punching mechanism,automatic bagmaking mechanism,product conveying mechanism,automatic bag opening mechanism,automatic bag loading mechanism,automatic sealing mechanism,product conveying and discharging mechanism,main support mechanism and controlmechanism;

2.The design of each component of the equipment shall be carried out according to the efficiency requirements of 900-1200PCS/H;

3.The equipment structure design is scientific,simple,highly reliable,easy to adjust and maintain,and easy to learn.