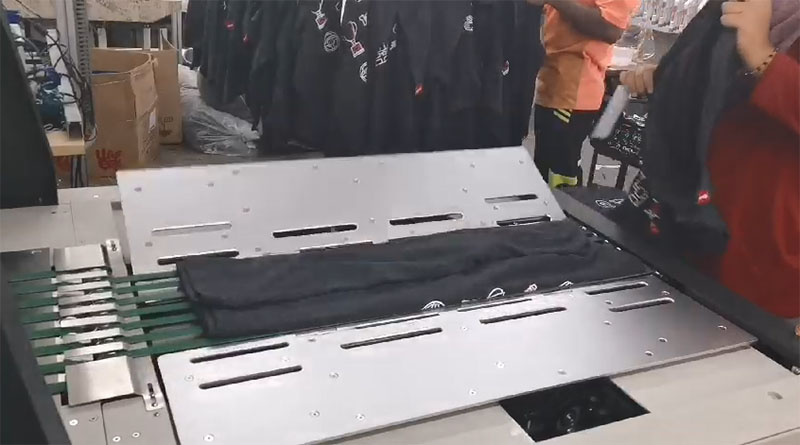

E-com sorting and shipping automated packaging solution

Equipment Function

1.Full process automation: From clothing folding, labeling, scanning to packaging, the whole process is automated to reduce manual intervention.

2.High speed and high efficiency: The fast packaging machine and the translation conveyor line ensure high production capacity, which is suitable for e-commerce, clothing and other industries.

3.Intelligent identification and sorting: The CCD scanning system realizes accurate identification, and the sorting conveyor line automatically classifies to improve the accuracy.

4.Flexible production: The cache conveyor line balances the production rhythm and adapts to the packaging needs of products of different batches and specifications.

5.Real-time data management: The real-time printing labeling machine dynamically generates labels and connects with the MES/ERP system to ensure accurate information.

6.Modular design: Each device operates independently and can be seamlessly connected, which is convenient for production line adjustment and expansion.

Packaging and shipping

Customer usage scenario diagram

Work shop