POD whole line solution

Equipment Function

1. Combination of high automation and semi-automation

Semi-automatic fast packing machine: provides a combination of manual assistance and machine automation, allowing a certain amount of manual intervention while ensuring efficiency;

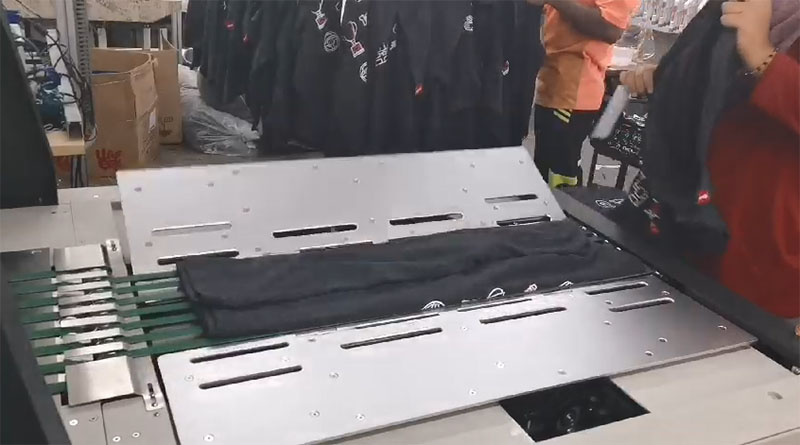

Garment automated folding machine: realizes fully automatic folding of clothing products and reduces manual operation links;

Real-time printing and labeling machine: automatically completes label printing and attachment without manual intervention.

2. Modular design;

The synthetic conveyor line connects each workstation to form a complete assembly line system;

Each device can operate independently or work together, which is convenient for maintenance and upgrading.

3. High-efficiency processing capacity

Fast packing machine: specially designed for high-speed packaging to improve the overall production line throughput;

Real-time printing and labeling: Instantly generate and attach labels to eliminate the bottleneck of label preparation time.

4. Multi-functional adaptability

Especially suitable for Garment industry applications (Garment automated folding machine);

Can handle packaging needs of different sizes and types (flexibility of synthetic conveyor lines).

5. Intelligent features

The real-time printing system can dynamically generate labels according to product information;

The automated folding machine can adapt to the folding requirements of different clothing styles.

6. Human-machine collaborative design

Semi-automatic equipment retains the manual operation interface, which is suitable for links that require manual quality inspection or special processing;

Fully automatic equipment handles work links with high repetitiveness and high degree of standardization.

7. Quality control support

Real-time labeling ensures accurate product identification;

Automated folding ensures consistency in product packaging appearance.

Packaging and shipping

Customer usage scenario diagram

Work shop